In the world of electric motors, particularly those used in HVAC systems, the dual run capacitor is a pivotal component that simplifies the design and enhances the efficiency of motors by combining two capacitors into one unit. Let’s delve into what a motor dual run capacitor is, its functions, and its advantages.

What is a Motor Dual Run Capacitor?

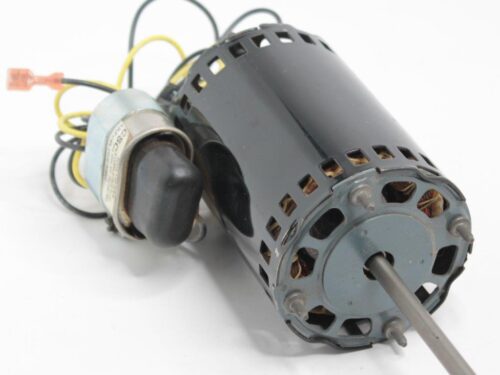

A motor dual run capacitor is essentially an electrical capacitor that integrates two capacitors with different capacitance values into one physical unit. It’s designed to facilitate the operation of two motors or a motor with two different functions, typically the compressor and the fan in an HVAC system. This dual-functionality component has three terminals instead of the usual two found on single capacitors: one common (C) terminal and two others for the fan (F) and the compressor (HERM).

Functionality and Operation

- Dual Capacitance: The dual run capacitor has two capacitance values: one for the start and run phases of the compressor (higher capacitance) and one for the fan motor (lower capacitance). This design allows a single capacitor to support two motors or motor functions simultaneously. This helps to optimize space and reduce the complexity of the wiring.

- Continuous Operation: Unlike start capacitors, the dual run capacitor remains active in the circuit as long as the motor(s) are running. It provides continuous phase shift and power factor correction for both the compressor and the fan motor, enhancing their efficiency and longevity.

Benefits of Using Dual Run Capacitors

- Space Efficiency: Combining two capacitors into one unit reduces the physical space needed for installation, an essential factor in the compact areas where HVAC units are often placed.

- Cost-Effective: Using one dual run capacitor instead of two separate capacitors can be more cost-effective regarding both parts and labor.

- Simplified Wiring: The design simplifies the wiring and connections needed within the motor or HVAC unit, reducing the potential for wiring errors or failures.

- Improved Reliability: With fewer components and connections, the overall reliability of the motor or system can be enhanced, reducing maintenance needs and potential downtime.

Applications

Dual run capacitors are predominantly used in HVAC systems where they support the operation of the outdoor unit’s compressor and fan motor. However, their use isn’t limited to HVAC systems; they can be found in any application where two motors or a motor with dual functions require capacitor support.

Replacement and Maintenance

- Like single capacitors, dual run capacitors need regular inspection, especially at the onset of the heating or cooling season. Signs of wear, such as bulging, leaking, or a rusted terminal, indicate the need for replacement.

- Correct sizing is crucial when replacing a dual run capacitor. The replacement must match the original capacitor’s specifications for both capacitance values and voltage rating to ensure proper operation and prevent motor damage.

Conclusion

Motor dual run capacitors represent an efficient, reliable solution in electric motor applications, particularly in HVAC systems. Understanding their role and maintaining them properly ensures the longevity and efficiency of the motors they support, ultimately enhancing the performance and reliability of the entire system.