Action Electric Drum Pump ACT-HDESS with upgraded Marathon 5KC39RN44GX 1 HP 115/208-230V 3450 RPM motor, 316 SS wet end, Teflon/Viton seal, 3/4″ FPT outlet, EPDM 1″-ID hose; max head 10.0 ft (water); viscosity guidance up to 2000 cPS

Original price was: $2,300.00.$1,390.00Current price is: $1,390.00.

1 in stock

Action Electric Drum Pump ACT-HDESS with upgraded Marathon 5KC39RN44GX 1 HP 115/208-230V 3450 RPM motor, 316 SS wet end, Teflon/Viton seal, 3/4″ FPT outlet, EPDM 1″-ID hose; max head 10.0 ft (water); viscosity guidance up to 2000 cPS for non-flammable compatible liquids

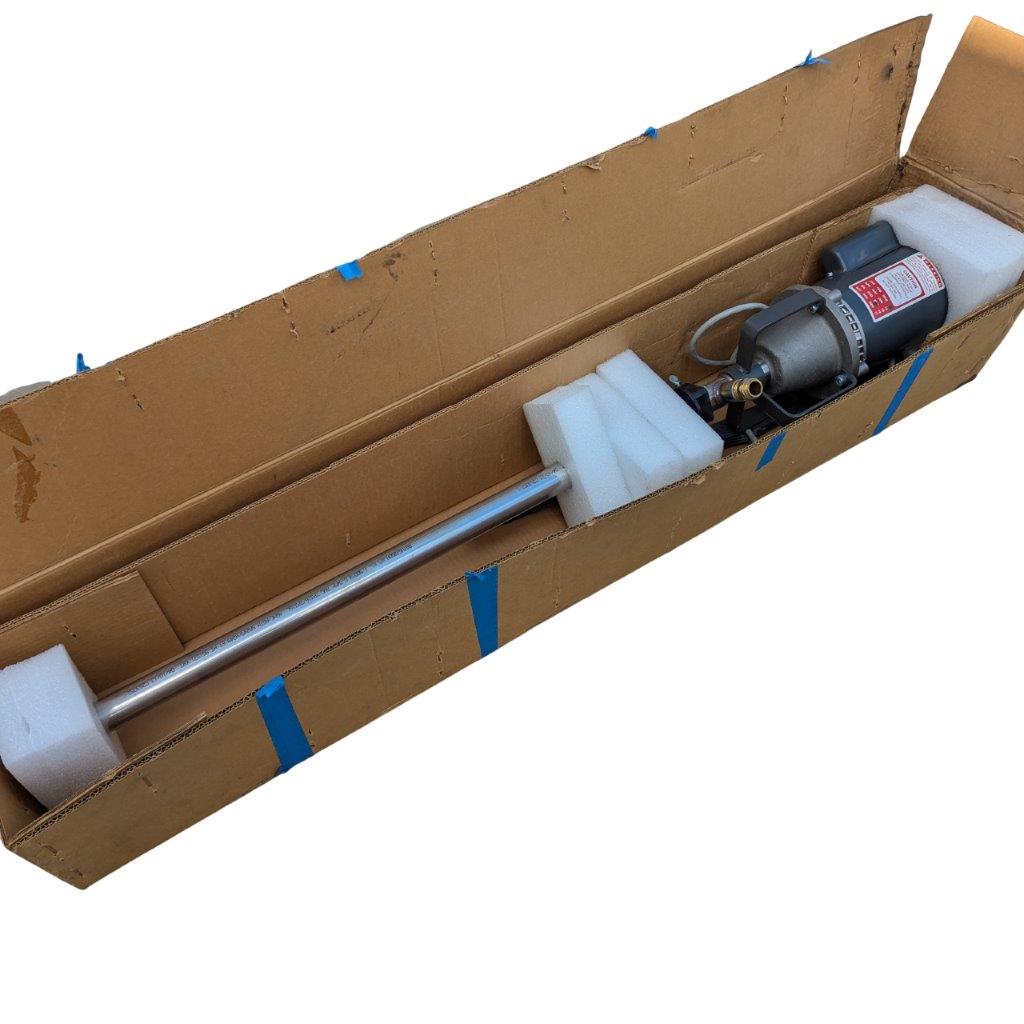

Condition: Used — in great shape, tested and working. Includes pump + motor assembly, 5-ft EPDM hose, manual, and original (distressed) box. No other deficiencies noted.

Overview

This listing is for an Action ACT-HDESS stainless electric drum pump that has been retrofitted with a Marathon Electric 5KC39RN44GX, 1 HP, 3450 RPM, single-phase, frame 56C motor. The wet end remains 316 stainless with Teflon impeller/auger and a Teflon mechanical seal with a Viton® O-ring isolating the motor from the liquid. The pump is self-priming and intended for clean, non-abrasive, non-flammable liquids compatible with 316 SS/Teflon/Viton.

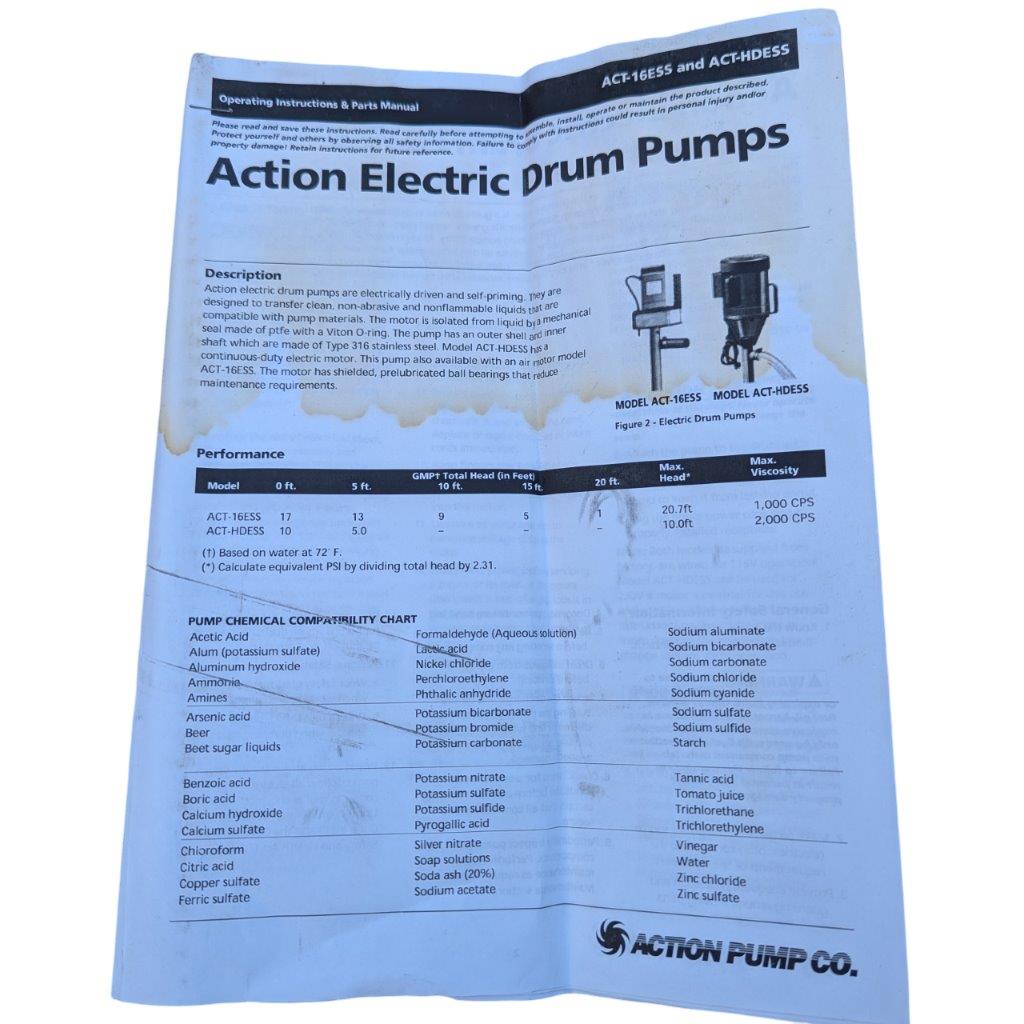

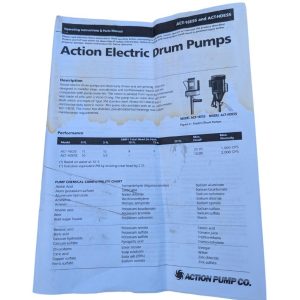

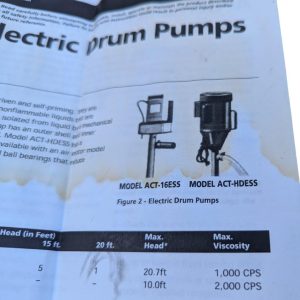

About the performance numbers you noticed

- The paper manual you have lists Max Head = 10.0 ft (water) and Max Viscosity = 2000 cP. Your head figure matches the factory table (10.0 ft), while the viscosity value differs from the PDF, which shows 500 SSU for ACT-HDESS.

- The PDF manual explicitly states ACT-HDESS to 500 SSU (a kinematic/time unit). 500 SSU at SG≈1 is roughly ~110 cP, far lower than 2000 cP. The head row in the same table shows 10.0 ft max.

Interpretation: your paper manual likely reports dynamic viscosity (cP), while the PDF uses SSU; they’re different units. If you’ll share your liquid’s temperature and specific gravity, I can pin the exact SSU↔cP conversion for your case.

Note: Upgrading to a higher-HP motor can improve available torque at the coupling but does not increase the pump’s hydraulic limits of head/viscosity established by the wet-end design. For reliable expectations, use 10.0 ft max head and the viscosity range validated for the wet end.

Features

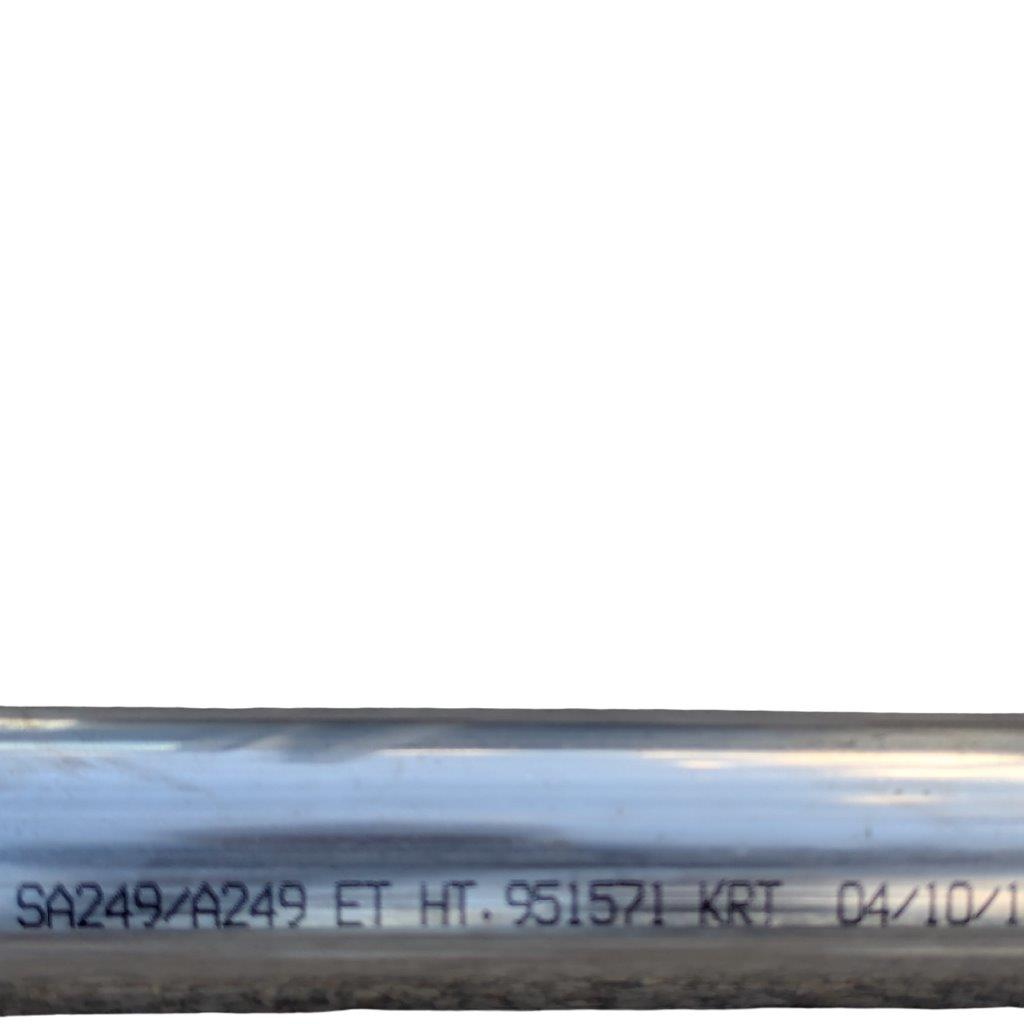

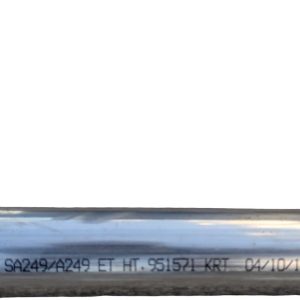

- 316 stainless-steel outer column and inner shaft for corrosion resistance.

- Teflon impeller & auger, Teflon seal with Viton O-ring for broad chemical compatibility (non-flammables).

- Self-priming electric drum pump design with simple flush-and-store maintenance.

- 3/4″ FPT discharge; includes 5-ft EPDM hose (1″ I.D.).

- Safety: not for flammable or explosive fluids/atmospheres; follow NEC/OSHA; GFCI recommended.

Specifications (as configured)

Pump/Wet End (factory data for ACT-HDESS):

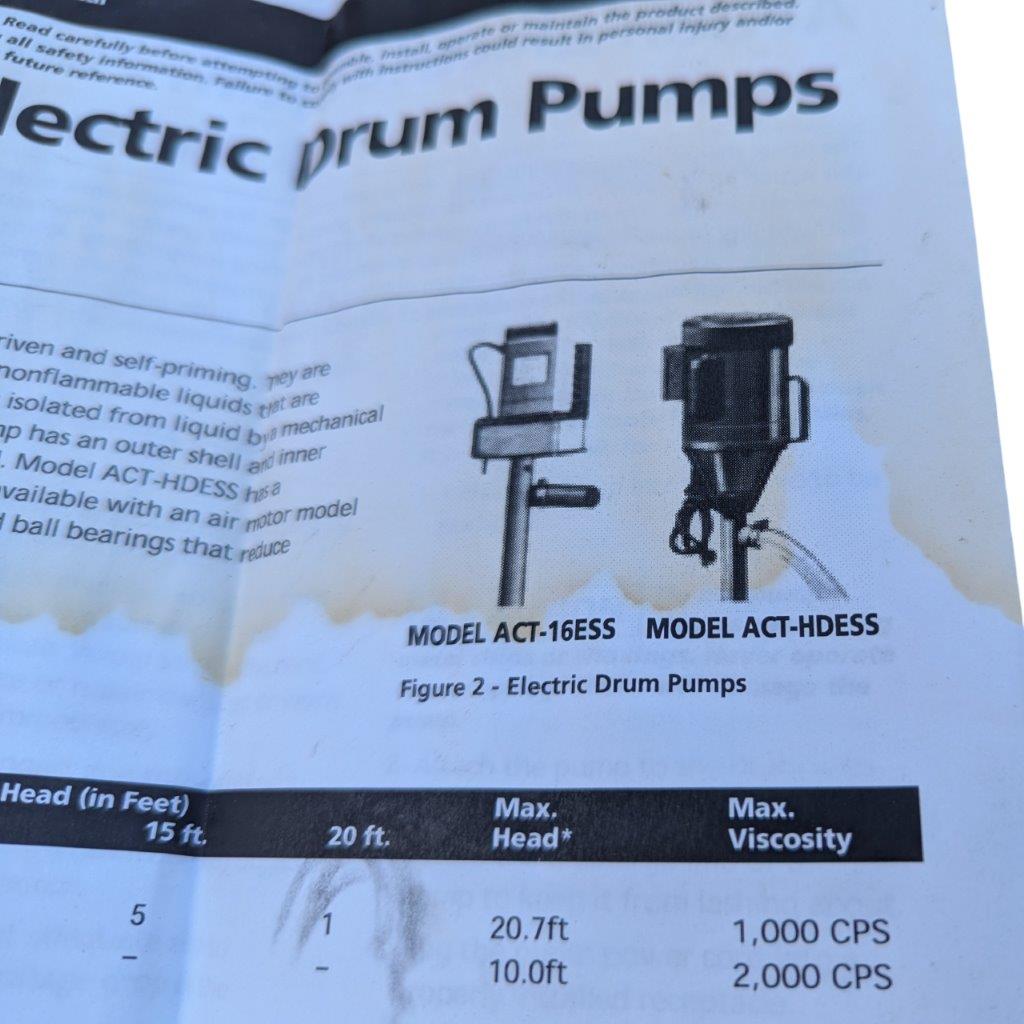

- Max Total Head (water): 10.0 ft; typical flows ~10 GPM @ 0 ft and ~5 GPM @ 5 ft (water, 72 °F).

- Viscosity guidance: included paper manual: up to 2000 cP; PDF manual: up to 500 SSU (≈110 cP @ SG≈1).

- Materials in contact: 316 SS column & shaft; Teflon impeller/auger/seal; Viton O-ring.

- Discharge connection: 3/4″ FPT; Hose: EPDM 5-ft, 1″ I.D.

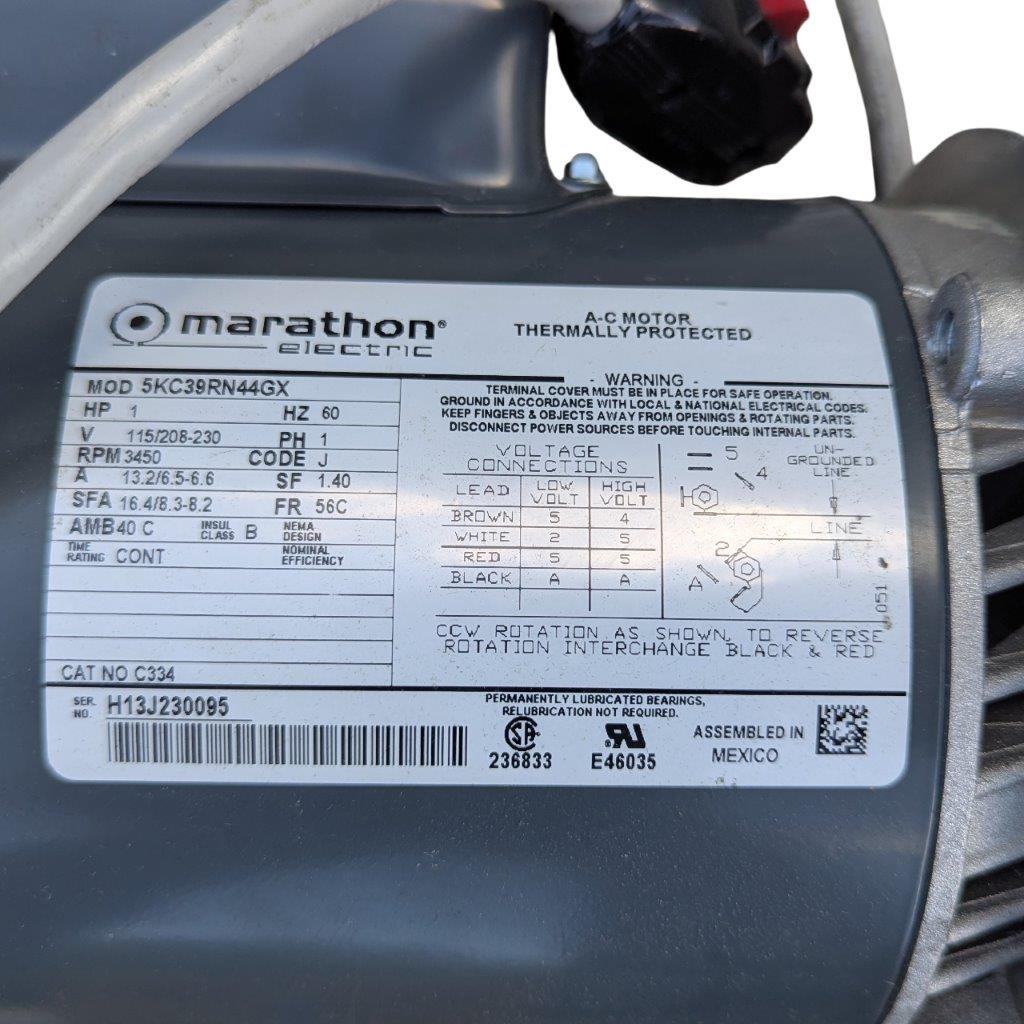

Installed Motor (current unit):

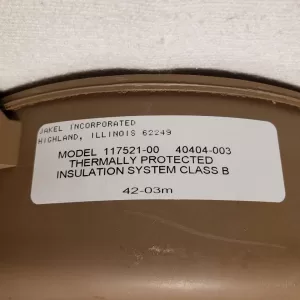

- Marathon Electric 5KC39RN44GX, 1 HP, 3450 RPM, 1-phase, 115/208-230 V, Frame 56C, Code J (per nameplate details).

- Replaces the catalog Dayton 6K181C (1/3 HP) referenced in the factory parts list.

Electrical / Use

- Factory docs note units ship wired 115 V; ACT-HDESS can be rewired for 230 V; use proper grounding/GFCI. Motor supports 115 or 208-230 V per nameplate.

Applications

- Transfer from 55-gal drums and totes of compatible non-flammable chemicals: water treatment salts/acids/bases, plating baths, soap solutions, food-adjacent non-flammables (e.g., vinegar, citric), and general plant liquids (see list).

- Batch make-up and day-tank top-off where total dynamic head is ≤10 ft and viscosity within guidance.

Chemical Compatibility (selected, per chart)

Acetic, citric, boric, lactic, tannic, sulfurous acids; alum; Na/K carbonates, chlorides, sulfates; ferric/copper/zinc salts; soap solutions; water; beer; beet sugar liquids; tomato juice. Always verify exact concentration, temperature, and SG and avoid flammables.

Cross-Referenced Models

- Original spec motor: Dayton 6K181C (1/3 HP) — parts list reference for ACT-HDESS.

- ACT-16ESS (air/universal motor version) — different motor, higher listed head on chart, but lower viscosity (100 SSU); not directly comparable to your electric model.

Comparable Products

- Similar stainless drum pumps with 316 SS/Teflon/Viton wet ends and ~10–15 ft head class from other industrial brands (ensure non-flammable service and equal materials).

- If your duty fluid is truly near 2000 cP, we may consider progressing cavity or high-torque drum pumps designed for higher viscosities.

What This Unit Can Be Part Of

- Drum transfer/dispense skids with inline flow meters and valves.

- Chemical batching to low-elevation tanks.

- Maintenance carts for non-flammable CIP/cleaner top-offs.

(Respect the 10-ft head limit and viscosity window for predictable flow.)

Included in This Sale

- ACT-HDESS pump with Marathon 5KC39RN44GX 1 HP motor (installed)

- 5-ft, 1″-ID EPDM discharge hose

- Manual and original box (distressed)

Not Included / Notes

- No additional nozzle/meter unless pictured; no spare augers/seals beyond what’s installed.

- If you need the original 6K181C wiring/parts details for reference, I can provide the relevant page numbers.

Related

action act-hdess drum pump; stainless 316 barrel pump; electric chemical transfer pump; 3/4 in FPT outlet pump; teflon impeller auger pump; viton o-ring chemical pump; epdm discharge hose; non-flammable liquid transfer; device to move liquids from drums; pump for acid solutions; low-head transfer pump; marathon 5KC39RN44GX retrofit; 56C frame pump motor; dayton 6K181C equivalent build; viscosity 2000 cP drum pump; 500 SSU stainless pump

Common Requests:

- “Can the ACT-HDESS (with 1 HP motor) handle 2000 cP glycerin at 70 °F, SG 1.26? What flow can I expect?”

- “Convert 500 SSU at 68 °F, SG 0.95 to cP and advise suitability for this pump.”

- “What’s the correct bung adapter and hose barb setup for 1” hose on the 3/4” FPT outlet?”

- “Flush procedure and recommended non-flammable rinse for sugar solution service.”

- “Compare ACT-HDESS vs a progressing-cavity drum pump for high-viscosity syrups.”

Manufacturer and product names, including Action™, Dayton®, Marathon Electric™, Teflon®, and Viton®, are trademarks or registered trademarks of their respective owners. Use of these names is solely to identify compatibility and specifications.

P122

| Weight | 32 lbs |

|---|---|

| Dimensions | 57 × 11 × 10 in |

You must be logged in to post a review.

Reviews

There are no reviews yet.